Nuclear Power Plant,

EPR (2 units), Somerset, UK

Owner/Operator: NNB, Subsidiary of EDF in the UK

Main contractor (civil works): BYLOR (Bouygues TP & Laing O’Rourke Joint Venture)

Post-Tensioning system used: FREYSSINET

Post-Tensioning system supply and installation: FVH (FREYSSINET and VSL Joint Venture)

![]()

![]()

Role of ELIAS: Technical manager

Project Description

Hinkley Point C (HPC) is a two-unit, 3,200 MWe EPR nuclear power plant under construction in Somerset, England. The project is financed by EDF Energy and China General Nuclear Power Group (CGN).

About Post-Tensioning

The EPR reactor building is made of a double-shell concrete containment. The inner-shell is densely post-tensioned (about 2400 tons of PT strands) with 3 types of tendon geometry:

- Vertical tendons (long and short)

- Gamma tendons

- 360° full-loop Horizontal tendons.

3 Types of PT tendon

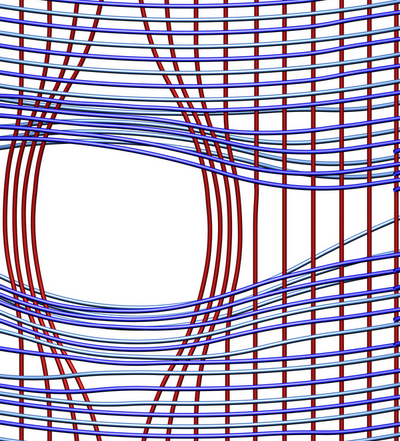

The tendons are deviated around the different hatches penetrating the reactor building. These deviations can reach up to 4.5 m height for horizontal tendons, increasing even more the cumulative angular deviation and the friction coefficient which are already particularly high for these tendons.

PT Cable Layout around equipment hatch

The PT system is made of 55 strands and is “bonded”: bared strands injected with cement grout.

The different cement grout formulas (preliminary tested in laboratory), as well as the corresponding grouting methods, are validated on full-scale grouting mock-ups prior to their implementation for permanent works. This grout validation process started in 2019 and is planned to be completed in 2023.

HPC Horizontal mock-up