Nuclear Power Plant,

VVER (2 units), Jiangsu, CHINA

Owner/Operator: Jiangsu Nuclear Power Corporation (Joint Venture between CNNP & CNNC)

Main contractor (civil works): ASE (AtomStroyExport) & CNPE (CNNC China Nuclear Power Engineering Co., Ltd.)

Post-Tensioning system used: VSL

Role of ELIAS: Technical Support Lead and Auditor

Project Description

Tianwan Nuclear Power Plant is a nuclear power plant located in the city of Lianyungang in Jiangsu Province, China. It is located on the coast of the Yellow Sea approximately 30 kilometers east of downtown Lianyungang. This NPP is owned by Jiangsu Nuclear Power Corporation, a joint venture mainly owned by the China National Nuclear Power Co., Ltd (CNNP),subsidiary of China National Nuclear Corporation (CNNC). This NPP currently counts 6 operational units and 2 units are under construction. Units 7 and 8 are expected to commence commercial operation in 2026 and 2027 respectively. If all the units are completed, Tianwan will become the world’s largest nuclear power plant with a total generating capacity of over 9,000 MWe.

The construction of Units 3 and 4 started in December 2012. Each unit capacity of Units 3 and 4 (Russian design VVER-1000) is rated at 1126 MWe. Units 3 and 4 entered commercial operation in February 2018 and December 2018 respectively.

About Post-Tensioning

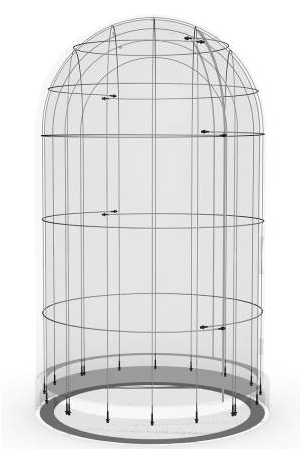

The VVER-1000 reactor building is made of a double-shell concrete containment. The inner-shell is densely post-tensioned (about 1400 tons of PT strands) with 2 types of tendon geometry:

- Inverted-U shaped Vertical tendons (with active anchorages at both ends of the tendons present in an underneath PT gallery)

- 360° full-loop Horizontal tendons spread on 2 opposite buttresses

2 tendon types of VVER

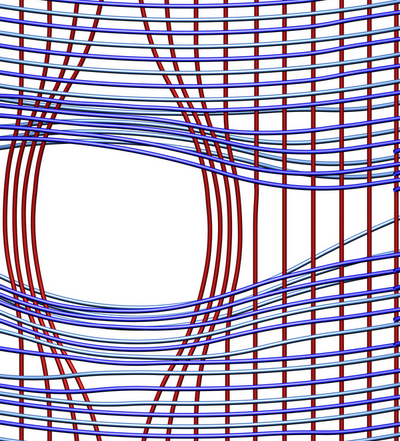

The tendons are deviated around the different hatches penetrating the reactor building. These deviations can reach up to 4.5 m height for horizontal tendons, increasing even more the cumulative angular deviation and the friction coefficient which are already particularly high for these tendons.

PT Cable Layout around equipment hatch

The PT system is made of 55 strands and is bonded: bare strands injected with cement grout.

Grouting operations of horizontal tendons