Construction Center,

Oblast of Murmansk, RUSSIAN FEDERATION

Owner/Operator: NOVATEK, through daughter company ARCTIC LNG-2

Main Contractor for civil works: SAREN (SAIPEM & RENAISSANCE Joint Venture)

Post-Tensioning system used: TENSA

Role of ELIAS: Project manager

Project Description

The project Arctic LNG-2 includes the construction of three LNG trains with a total capacity of 19.8 MTPA of Liquefied Natural Gas (LNG) and up to 1.6 MTPA of Stable Gas Condensate (SGC).

Arctic LNG-2 liquefaction trains

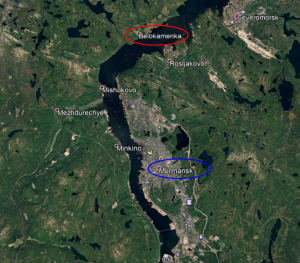

The main construction worksite is the LNG Construction Center (“Center”) located in the village of Belokamanka («Белокаменка»), in the Oblast of Murmansk («Мурманская область»), at about 50 km from the city of Murmansk, on the opposite side of Kolskyi Gulf in the northern part of Russia.

Arctic LNG-2 Center location in Belokamenka

The Center includes 2 dry docks in which the liquefaction trains are erected. It is a key facility for the LNG equipment manufacturing industry emerging in Russia. Each liquefaction trains employs an innovative construction concept using one concrete Gravity-Based Structure (“GBS”) that supports steel structures ( “Topsides”) made of 14 modules.

Construction process and Topside module assembly illustrated in 3d Animation

About Post-Tensioning

GBS are huge concrete structures densely post-tensioned (more than 11000 tons of PT strands each) in all 3 main space directions: vertically, longitudinally, and transversally.

The tendons are made of 12, 19 or 31 strands depending on their location on the GBS structure.

Among the several challenges of the installation of post-tensioning on such project, we can highlight some key ones:

- The installation of “long” tendons up to 330 m long with slight horizontal deviations

- The “huge” quantity of strand coils to store, maintain, handle, lift, and dispatch on 2 GBS built simultaneously with several working fronts

- The extreme cold arctic region conditions significantly limiting the available period of time suitable for grouting activities and works with hydraulic equipment (like jacks for tendon stressing)

- The “huge” quantity of vertical tendons (more than 1200 tendons per GBS) accessible only from an highly congested space (Top slab)

Each dry dock is equipped with a concrete Dry Dock Gate (“DDG”), concrete structure also densely post-tensioned longitudinally.

Stressing operation on Arctic LNG-2 in April 2022