Nuclear Power Plant,

VVER (2 units), Oblast of Leningrad, RUSSIA

Owner/Operator: ROSENERGOATOM

Designer / Main contractor (project): ATOMPROJEKT SPB, TITAN-2

Main contractors (civil works): METROSTROY for Unit 1, GIDROMONTAZH for Unit 2

![]()

Post-Tensioning system used: VSL

Role of ELIAS: Project Manager

Project Description

Leningradskaya Nuclear Power Plant (Russian: “Ленинградская атомная электростанция” or “Ленинградская АЭС” or LAES) is a nuclear power plant located in the town of Sosnovyi Bor in Russia’s Leningrad Oblast, on the southern shore of the Gulf of Finland, about 70 kilometers to the west of the city centre of Saint-Petersburg.

The nuclear town of Sosnovyi Bor houses four nuclear reactors of the RBMK-1000 type, all of which are first generation units. In 2008, construction started on Leningradskaya-2 with 2 VVER-1200 type reactors. They will eventually replace the RBMK units as they are shut down due to age.

Leningradskaya-2 Unit 1 started commercial operation in October 2018 and Leningradskaya-2 Unit 2 entered commercial operation on March 2021.

LAES-2 Construction site in 2011

Video of the project LAES-2 completed

About Post-Tensioning

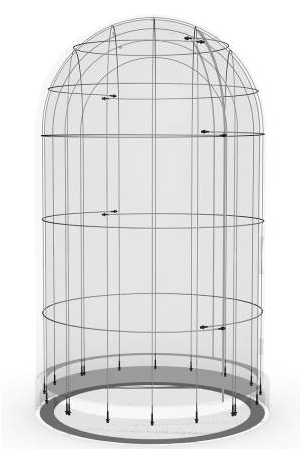

The VVER-1200 reactor building is made of a double-shell concrete containment. The inner-shell is densely post-tensioned (about 1400 tons of PT strands) with 2 types of tendon geometry:

- Inverted-U shaped Vertical tendons (with active anchorages at both ends of the tendons present in an underneath PT gallery)

- 360° full-loop Horizontal tendons spread on 2 opposite buttresses

2 tendon types of VVER

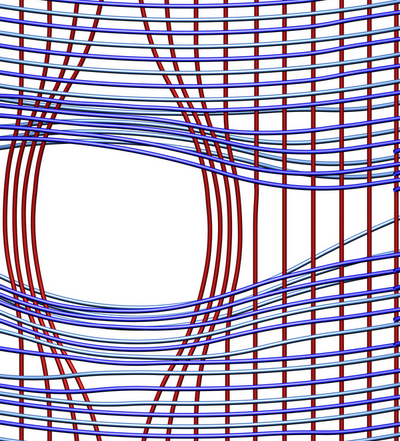

The tendons are deviated around the different hatches penetrating the reactor building. These deviations can reach up to 4.5 m height for horizontal tendons, increasing even more the cumulative angular deviation and the friction coefficient which are already particularly high for these tendons.

PT Cable Layout around equipment hatch

The PT system is made of 55 strands and is unbonded: greased & sheathed strands (also called “monostrands”) injected with cement grout.